Corrugated Boxes

At Deluxe Packaging, we know the importance of properly packaging your products every step of the way, from production and fulfillment to function and display. With custom and stock options, we offer a variety of corrugated boxes that are cost-effective, sustainable, flexible, and easy to assemble.

About Corrugated Boxes

Slotted box styles are generally made from one piece of corrugated or solid fiberboard. The blank is scored and slotted to permit folding. The box manufacturer forms a joint at the point where one side panel and one end panel are brought together. Boxes are then shipped flat to the user. When the box is needed, the box user squares up the box, inserts the product, and closes the flaps.

When you partner with Deluxe Packaging, you have access to the following:

- Full-Service Box Manufacturer. As a full-service box manufacturer, we offer complete packaging solutions from design and production through delivery with value-added services including contract fulfillment, assembly services, and point-of-purchase assembly and display.

- Vendor Managed Programs. Enjoy a simplified packaging process by partnering with our vendor managed program options.

- Just in Time Delivery. We can help you save valuable time, space, and labor costs with a streamlined supply chain process.

- Full Design Capability with CAD Table. Our experienced design team and industry-leading technology are ready to partner with you to design and produce custom packaging with your requirements.

- Cost Savings Programs to Reduce or Eliminate Packaging. We can work with you to design and select the most cost-effective way to package your products while maintaining the quality and features you want.

- Product Design and Testing. With decades of experience in packaging production, our design and testing services ensure your product and packaging are paired successfully.

- Custom Corrugated Packaging. We offer custom packaging services to satisfy any shape, style, and function requirements.

Types of Corrugated Boxes

We manufacture corrugated boxes and cartons in dozens of shapes and styles to accommodate nearly any packaging need. Stock varieties include multiple sizes of one- and two-piece designs, folders, dividers, and more. We know that having the perfect fit is important, so we also offer custom corrugated packaging services and offer a variety of staples, designs, and colors to suit the needs of any packaging application.

Types of corrugated boxes we offer include:

Slotted

Slotted boxes are the most commonly used style of corrugated box, and they are manufactured with almost no waste. Made from a single piece of material, they are scored and cut (slotted) for easy folding and assembly. We offer many variations of slotted boxes to suit the needs of any application.

Slotted boxes have endless uses. They can be used for shipping, storage, retail packaging, and more in nearly any industry from food and beverage and pharmaceuticals to automotive, chemical, and more.

Telescoping

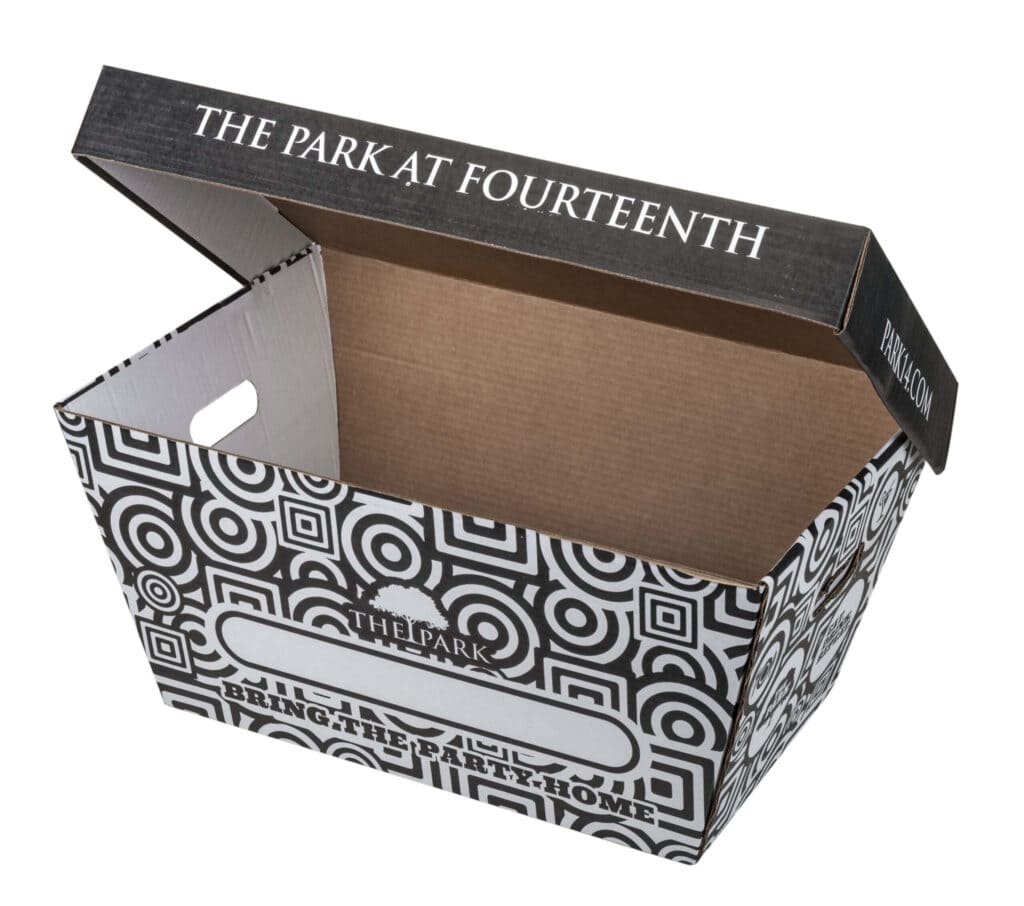

Telescoping boxes use a two-piece design where the lid is only slightly larger than the bottom piece (tray). When closed, the lid extends over the sides of the tray either partially or all the way to the bottom, adding stacking strength and ease of opening.

Telescoping boxes are commonly used for everything from moving and shipping boxes to display and retail packaging boxes across many industries. Sturdier telescoping boxes are frequently used in shipping fresh produce and in packaging bulky and heavy items, allowing products to be easily removed from packaging.

Folders

Folder style boxes are designed with a solid bottom and overlapping flaps that are scored so the box can be wrapped or folded around a product. This style of box is often used for shipping books and other printed materials as well as for shipping smaller products, often with skin packaging protection.

Corrugated Mailers

Corrugated mailers, also known as corrugated shipping boxes, are easy to assemble and offer protection for shipped products. These boxes can be customized to illustrate your brand and come in a variety of colors to enhance aesthetic appeal and customer experience. Corrugated mailers can be used to ship small or many products and are commonly used for e-commerce and subscription box packaging.

Partner With Deluxe Packaging

At Deluxe Packaging, we have decades of experience as a corrugated box manufacturer, designing and creating superior products for every type of packaging need. To learn more about our capabilities, or to get started on your packaging solution, contact us or request a quote today.

0201 Regular Slotted Container (RSC)

All flaps have the same length, and the two outer flaps (normally the lengthwise flaps) are one-half the container’s width, so that they meet at the center of the box when folded. If the product requires a flat, even bottom surface, or the protection of two full layers, a fill-in pad can be placed between the two inner flaps. This is a highly efficient design for many applications. There is very little manufacturing waste. The RSC can be used for most products and is the most common box style.

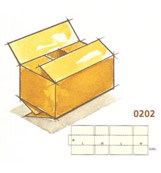

0202 Overlap Slotted Container (OSC)

All flaps have the same length. The outer flaps overlap by one inch or more. The box is easily closed, usually with staples driven through the overlap area. This style is used when the length of the box is considerably greater than the width, resulting in a long gap between the inner flaps. The sealed overlap helps to keep the outer flaps from pulling apart.

0203 Full Overlap Slotted Container (FOL)

All flaps have the same length (the width of the box). When closed, the outer flaps come within one inch of complete overlap. The style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.

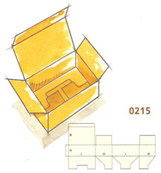

0215 Snap or 1-2-3 Bottom Container with Tuck Top

The four flaps that form the bottom panel are die cut. To set up, the user folds the largest bottom panel first, then the two end panels. When the remaining bottom panel is folded and pressure is applied near the center, the flap “snaps” into the slot created by the other panels. The style is convenient for small-volume shippers who do not have automatic set-up equipment. Because the bottom is not fully sealed, it may not be suitable for heavy products.

0216 Snap or 1-2-3 Bottom Container with RSC Top

The four flaps that form the bottom panel are die cut. To set up, the user folds the largest bottom panel first, then the two end panels. When the remaining bottom panel is folded and pressure is applied near the center, the flap “snaps” into the slot created by the other panels. The style is convenient for small-volume shippers who do not have automatic set-up equipment. Because the bottom is not fully sealed, it may not be suitable for heavy products.

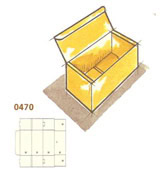

0228 Integral Divider Container, RSC with Internal Divider or Self Divider Box

Telescope boxes usually consist of a separate top, or top and bottom, that fit over each other or a separate body. The International Fibreboard Case Code calls these boxes Telescope-Style. The truck and rail classifications call them Telescope Boxes if the cover extends over at least two-thirds of the depth, and Boxes with Covers if the cover extends over less than two-thirds of the depth.

0301 Full Telescope Design Style Container (FTD)

The two-piece box is made from two scored and slotted blanks (trays).

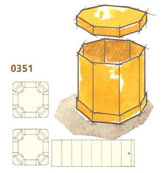

0351 Octagonal Double Cover Container (DC)

A tube forms the body. The two interchangeable covers are usually design style. The pieces are shipped flat to the user, who opens the tube and sets up the covers. The style is frequently used for tall or heavy products that would be difficult to lower into a box. The item is placed on the bottom cover, and the tube is lowered over the product. For Folders, one or more pieces of combined board provide an unbroken bottom surface, and are scored to fold around a product.

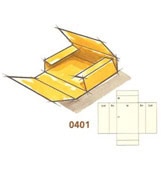

0401 One Piece Folder (OPF)

One piece of board is cut so that it provides a flat bottom, with flaps forming the sides and ends, and extensions of the side flaps meeting to form the top.